MAINTENANCE STRATEGY: Corrective Maintenance

MAINTENANCE STRATEGY

Companies utilize a range of maintenance strategies, incorporating both...

By: Jorma Manninen on Jan 23, 2024 5:09:15 AM

Discover how to evaluate maintenance performance with this comprehensive step-by-step guide. Learn the key metrics, tools, and strategies to assess and improve maintenance operations.

Maintenance performance evaluation is crucial for any organization to ensure efficient and effective operations. By assessing the performance of maintenance activities, organizations can identify areas of improvement and make informed decisions to optimize their maintenance processes. Evaluating maintenance performance helps organizations understand the impact of maintenance on overall operations, equipment reliability, and cost management.

A thorough understanding of the importance of maintenance performance evaluation enables organizations to prioritize maintenance activities based on their significance and criticality. It helps in allocating resources effectively, reducing downtime, and maximizing equipment availability. Additionally, maintenance performance evaluation provides insights into the effectiveness of maintenance strategies, allowing organizations to make data-driven decisions for continuous improvement.

To assess maintenance performance accurately, organizations need to identify key metrics that align with their maintenance objectives and goals. Key performance indicators (KPIs) play a vital role in measuring and evaluating maintenance performance. Some common KPIs for assessing maintenance performance include equipment uptime, mean time between failures (MTBF), mean time to repair (MTTR), planned maintenance percentage, emergency maintenance percentage, and maintenance backlog.

By tracking these metrics, organizations can gain insights into the reliability, availability, and performance of their assets. These metrics help in identifying patterns, trends, and potential issues that impact maintenance performance. Moreover, they provide a basis for benchmarking and setting performance targets, enabling organizations to monitor progress and drive continuous improvement.

Data and analytics play a crucial role in measuring maintenance performance accurately. By collecting and analyzing relevant maintenance data, organizations can gain insights into the effectiveness of their maintenance strategies and identify areas for improvement. Advanced analytics techniques, such as predictive maintenance and condition monitoring, help in detecting equipment failures before they occur, reducing unplanned downtime, and optimizing maintenance schedules.

Furthermore, data-driven decision making enables organizations to prioritize maintenance activities based on criticality, allocate resources efficiently, and optimize maintenance budgets.

By leveraging maintenance management software and predictive analytics tools, organizations can streamline data collection, analysis, and reporting processes, making maintenance performance evaluation more efficient and effective.

Continuous improvement is essential for enhancing maintenance performance and achieving operational excellence. Organizations should establish a culture of continuous improvement by fostering collaboration, encouraging feedback, and promoting learning across maintenance teams. By regularly reviewing maintenance processes, identifying bottlenecks, and implementing corrective actions, organizations can drive efficiency and effectiveness in maintenance operations.

Implementing reliability-centered maintenance (RCM) methodologies, such as failure mode and effects analysis (FMEA), can help in identifying failure modes, their effects, and suitable maintenance strategies. Additionally, organizations should prioritize preventive maintenance, implement proactive maintenance practices, and invest in training and development programs to enhance the skills and knowledge of maintenance personnel.

Continuous improvement strategies also involve leveraging technology innovations, such as Internet of Things (IoT), artificial intelligence (AI), and machine learning (ML), to optimize maintenance operations. These technologies enable real-time monitoring, predictive maintenance, and condition-based maintenance, resulting in improved asset reliability, reduced downtime, and increased overall equipment effectiveness (OEE).

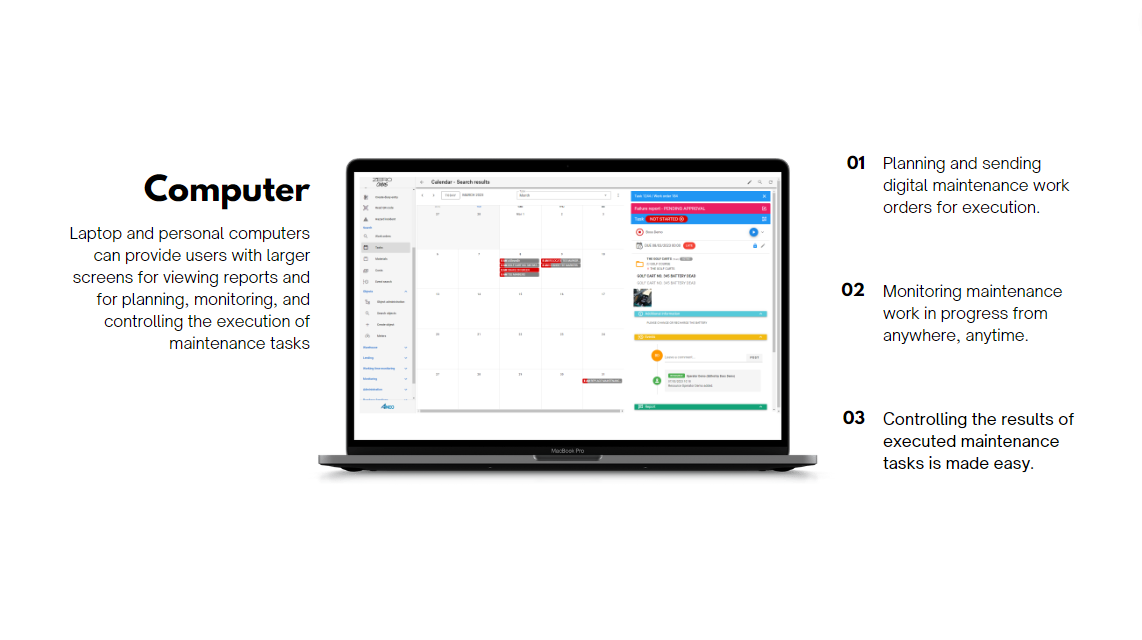

Technology plays a vital role in efficient maintenance performance evaluation. Organizations should leverage traditional computerized maintenance management systems or modern cloud-based maintenance management software (CMMS) to streamline maintenance processes, capture accurate data, and generate insightful reports. These systems help in tracking maintenance activities, managing work orders, scheduling preventive maintenance, and documenting maintenance history.

Furthermore, organizations can use advanced technologies, such as remote monitoring sensors, IoT devices, and predictive analytics platforms, to collect real-time data, monitor asset health, and predict maintenance needs. By leveraging technology, organizations can automate data collection, minimize manual efforts, and gain real-time visibility into their maintenance performance.

In conclusion, evaluating maintenance performance is crucial for organizations to optimize their maintenance operations. By understanding the importance of maintenance performance evaluation, identifying key metrics, utilizing data and analytics, implementing continuous improvement strategies, and leveraging technology, organizations can enhance their maintenance performance, reduce costs, and improve overall operational efficiency.

Download a Self-assessment Guide for Maintenance Organizations for free!

Companies utilize a range of maintenance strategies, incorporating both...

Companies utilize a range of maintenance strategies, incorporating both...

Companies utilize a range of maintenance strategies, incorporating both...